Service

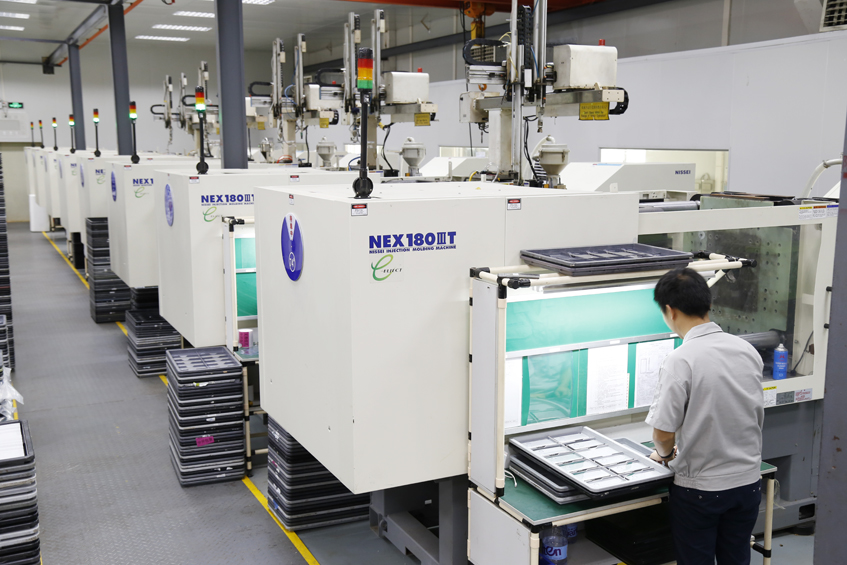

The company has 138 injection molding machines with tonnage ranging from 160T-1000T, all equipped with robots, minimizing the production cycle, reducing manpower, and most importantly, ensuring the stability in the production process, producing high-volume, high-precision injection molded parts. It is our advantage.

The company has been working hard to make high-precision injection molded parts. We have gained rich experience because customers have strict requirements on injection molded parts. As the most reliable Chinese supplier for our customers, we can manufacture large quantities of high quality injection molded parts.

Our engineers in the injection molding, mold making and quality departments work closely together to produce high-quality plastic products. Quality and service are our commitment to establishing long-term relationships with our customers.

Advantages of the injection molding sector:

► 4 injection molding workshops, including SUMITOMO, NISSEI, TOYO, DONGHUA, YIZIMI electric injection molding machines, with good production stability;

► Each injection molding machine is equipped with an automatic robot;

► Can provide injection moldings to some high quality companies in the world, such as VIVO, BBK, Littelfuse, etc.;

► Mass production or trial production. We can provide the best quality and the right price, and guarantee the timely delivery of your goods, saving you time and money.

► High precision: tolerances for injection molded parts can be achieved: +/- 0.02mm

► Plastic functional parts: OA plastic parts, POS accessories, mobile phone accessories, automotive plastic parts, printer accessories, etc. that need to be assembled accurately;

► Plastic parts: two-color products, electrical products, high-precision plastic products, water purifier accessories, air purifier accessories, etc.

We use a wide range of plastic materials as follows: